HiTen Buildings are an alternative to Structural Steel Buildings (Red Ox, PEB, Weldup) or Post Frame

(pole barn or stick frame).

Where do HiTen Buildings sit in the marketplace?

HiTen Buildings suit the 20 to 100+ foot clear span range (subject to component availability) and are ideal for domestic, industrial, and commercial buildings. Designs can include lean-to’s, mezzanine floors, and overhangs and have the strength of structural steel without the weight and the frames are galvanized to last for a lifetime.

HiTen Buildings

Design to suit

Wide Use

Economical choice

Superior strength

Delivery

Fast to produce

HiTen Buildings are produced by manufacturers using roll forming machines by taking large steel coils and running those through a series of rollers to form them into shapes used in HiTen Buildings.

Engineering/Approval Drawings are typically ready in 1-5 business days, and the building package is typically delivered to the job site in 3-5 weeks anywhere in the United States.

Component Finishes

Engineered for location

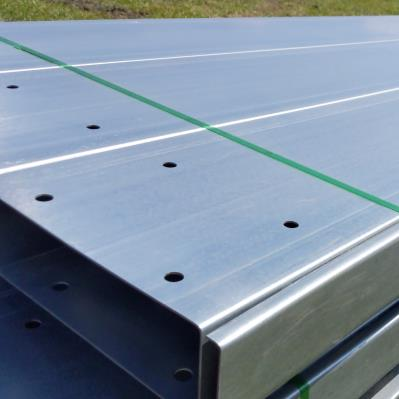

HiTen Buildings come with a galvanized finish. The galvanized finish comes direct from the steel mill and is an integral part of the steel. The galvanized steel won’t flake, rust, or require painting and it will last a lifetime.

HiTen’s components are engineered specifically for the building location. The main frame steel will vary from 4” to 24” in depth and 2 ½ to 5” wide, the gauge varies from 16ga to 10ga.

HiTen’s main frame is typically both bolted and screwed together using pre-drilled plates. HiTen Buildings can require some cutting/coping and drilling of braces on site.

Foundations

Save on concrete

HiTen Buildings bolt to the foundation (slab, piers, strip) using steel base plates and drill in anchors supplied with the building.

Anchors are installed after the concrete is complete. Engineered foundation plans are supplied with the building.

Depending on the size of the building, owners can typically save 20-25% less concrete than with structural steel building.

Economical choice

Endless options

Building Sizes

– designs can be as accurate to 1/16” increments for width, height, length

– length, no limit

– width, typically 10’ to 100’ clearspan

– Height, typically 8’ to 20’

4 foot is the smallest height provided and 30 foot is the tallest height provided

Erection

Experienced HiTen Buildings crew of 3:

– 4 days to erect 30’x40’x10’ Gable

– 14 days to erect 60’x80’x14’ Gable

– 15 days to erect 40x50x14 American Barn

Erection is not as physically difficult as a structural steel building due to the individual

components not being as heavy.